Meeting Purpose: Finalize Final Report

Meeting Date: 2/6/2021(Wendnesday)

Meeting Time: 9.00 p.m

Meeting Location: MS Teams Platform

Meeting

Facilitator: Muhammad

Nasir bin Aziz

Attendees: Mohamad Saifullah bin Zolkefly, Muhammad

Firdaus bin Khalid

Decision Made:

Division of report part

Discussion:

At the beginning of week 17, we have divided the task

to each person in preparing the remaining report which is 2 chapters. Chapters

1 and 2 are ready to be merged in the 15th week.

Conclusion:

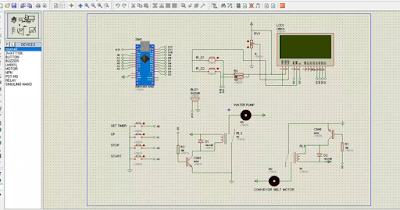

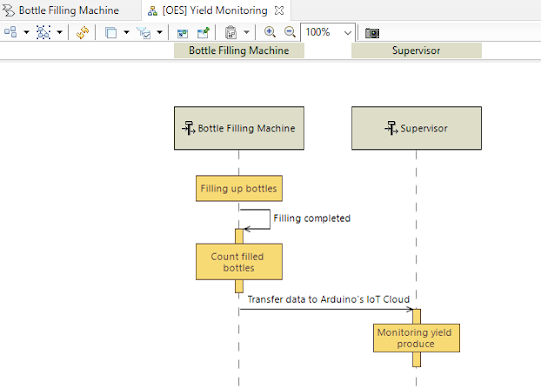

Chapter 3 which discusses the methodology is broken down into several parts, among which are input and output, flowchart and block diagram. Capella software is emphasized in this chapter. Step by step will be shown in the income of capella. Another software that is also used is proteus simulation for project demonstration use. Block diagram show the main processor input and output, interface to the internet. Types of architecture also show functional, physical and allocated.

Finally for chapter 4 is the results and discussion, this result is the result to Capella and Protues simulation, also discussed is the testing plan deployment and maintenance involved in this project.

Updated by: Muhammad Nasir bin Aziz